MES Solution Empowers the Electronic Ceramics Manufacturing Industry to Upgrade to Intelligent Manufacturing

Date:2025-10-11 Views:243

In the current wave of rapid advancement towards intelligent manufacturing in the manufacturing industry, electronic ceramics, as an important component of the high-end manufacturing sector, the refined, transparent,

and digital management of its production process has become the key for enterprises to enhance their competitiveness. Based on in-depth industry understanding and technological accumulation, a comprehensive and

efficient MES (Manufacturing Execution System) solution has been tailored for multiple electronic ceramics limited companies, aiming to promote the transformation and upgrading of electronic ceramics manufacturing

enterprises from traditional production to intelligent manufacturing.

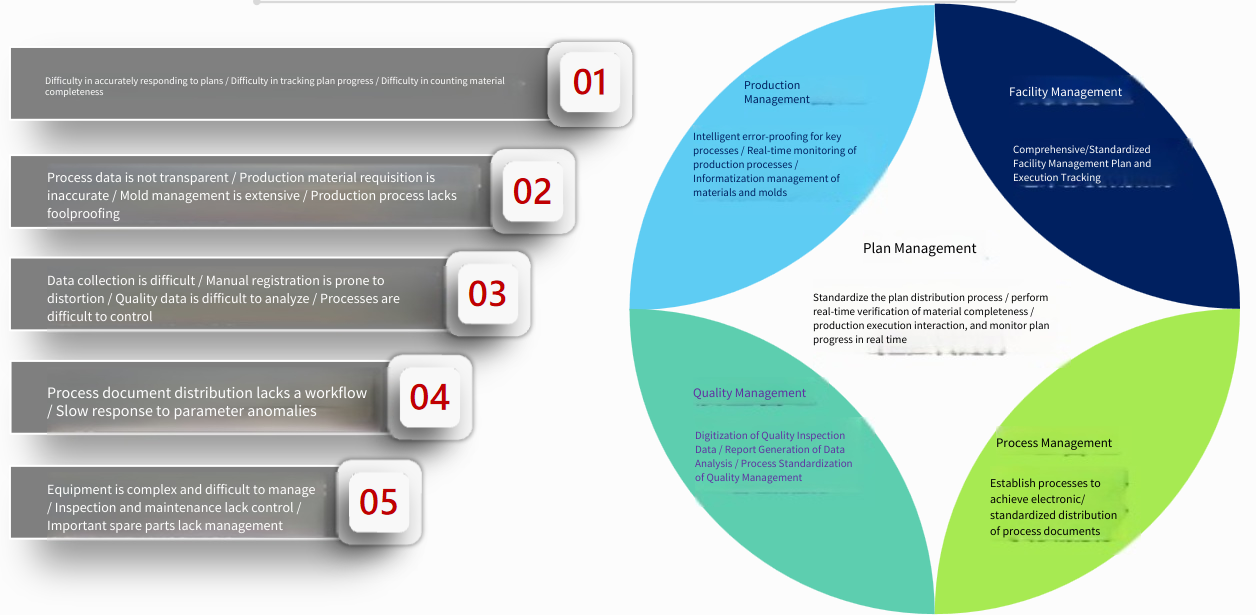

Industry Pain Points and Transformation Needs The production process of electronic ceramic products is complex and involves numerous procedures, covering multiple stages such as granulation, molding, sintering, metallization, and brazing, and faces challenges

such as a wide variety of equipment, difficult data acquisition, and long quality traceability chains. A company in Hunan, specializing in the production of products such as relay ceramic housings and power battery cover

ceramics, faces typical problems such as the disconnection between production planning and execution, opaque processes, extensive facility management, scattered quality data, and low traceability efficiency. Traditional

paper-based transfer cards and manual recording methods can no longer meet the high requirements of modern manufacturing for efficiency, quality, and traceability. Core Value of MES System The MES system, with the goals of "digitalization, transparency, lean management, and agility", has built an intelligent management platform that covers the entire production process. The system not only achieves full-chain

digitalization from plan issuance, material requisition, production execution, quality inspection to facility management, but also provides enterprises with intuitive and efficient management tools through functions such as 3D

visualization, mobile APP, and real-time dashboards.

1. Efficient collaboration between planning and execution The system supports synchronizing monthly production plans from ERP and flexibly splitting them into daily plans, supports complex scenarios such as order insertion, order cancellation, and over-reporting work audit, ensuring

real-time linkage between plans and production, and greatly improving production response speed and order fulfillment rate.

2. Full visibility throughout the production process Through functions such as barcode management, batch tracking, process reporting, and parameter entry, the system has achieved data acquisition and monitoring throughout the entire process from material input to output.

Employees can report production status in real-time via mobile terminals, and managers can view information such as production progress, equipment status, and quality anomalies at any time, truly realizing "one-code traceability

and one-screen control". 3. Rigorous Quality Management System The system supports multiple types of inspection tasks, such as initial inspection, patrol inspection, final inspection, process inspection, and outbound inspection, and has functions such as SPC analysis, defective product statistics,

and quality traceability. By standardizing inspection processes and collecting quality data in real time, enterprises can quickly identify quality issues, optimize process parameters, and continuously improve product qualification rates. 4. Intelligent Facility Management The system implements full lifecycle management of equipment ledger, inspection, maintenance, patrol inspection, spare parts management, etc., and supports functions such as fault repair reporting, maintenance tracking,

and energy consumption monitoring. Through preset maintenance plans, automatic task generation, and real-time early warning reminders, it effectively improves equipment utilization and reliability.

5. Precise Mold Management In response to the high dependence on molds in the electronic ceramics industry, the system provides full-process management functions such as mold warehousing, requisition, replacement, scrapping, and life warning,

enabling serial number-level fine control of key molds and avoiding production interruptions or quality fluctuations caused by mold issues. Implementation Results and Future Outlook The implementation of the MES system in a company in Hunan not only addresses the current pain points in production, such as excessive material requisition, chaotic ticket management, and lagging data statistics, but also

builds a sustainable and optimized intelligent manufacturing foundation platform for the enterprise. Through the comprehensive application of the system, the enterprise has achieved digitalization and transparency of the

production process and high efficiency of management, laying a solid foundation for the subsequent promotion of advanced applications such as industrial Internet, big data analysis, and artificial intelligence. In the future,

we will continue to deepen our MES solutions in the electronic ceramics industry, integrating new technologies such as the Internet of Things, Cloud Service, and Digital Twin, to help more manufacturing enterprises achieve

leapfrog development in intelligent manufacturing and contribute more to the transformation and upgrading of China's manufacturing industry. Our company specializes in intelligent manufacturing system solutions, committed

to providing customers with one-stop services from consulting, design, implementation to operation and maintenance, and helping enterprises move towards the era of Industry 4.0.