Digital transformation tool for the electronics industry: MES system

Date:2025-09-16 Views:280

In today's fiercely competitive market environment in the electronics industry, enterprises are facing many challenges such as rapid product updates, complex production processes, and high quality requirements. In order to address these challenges and enhance the core competitiveness of enterprises, more and more electronic manufacturing companies are introducing MES (Manufacturing Execution System). The MES system, as a key link between the enterprise planning layer and the production control layer, can achieve digital and intelligent management of the production process, bringing significant benefits to the enterprise.

1、 Objective of MES system construction:

Through the interconnection and integration of MES system, data acquisition system, and production line equipment, workshop production can be digitized, digitized, lean, and agile. With MES system as the core, full business flow management is carried out for production orders, planning and scheduling, production execution, and quality traceability. Through integration with data collection system, real-time collection and monitoring of workshop equipment production status, production processing parameters, and task information are achieved. Specifically achieve the following five construction goals:

1. Comprehensive equipment management: Through the system equipment management function module, scanning codes on mobile devices enables equipment inspection, maintenance, and other functions, as well as historical equipment ledger management and critical spare parts life management;

2. Establish a data collection platform: realize data collection of production workshop related equipment, as well as energy, safety, and environmental data collection, including temperature, humidity, VOC, etc., to achieve real-time alarm, warning prompt, and reduce production abnormality rate;

3. Realize comprehensive business data flow management: Implement electronic management of process cards, self inspection record forms, special inspection record forms and other forms involved in the production process, display them through reports and dashboards, integrate production and business data, enhance factory transparency, comprehensively and intuitively display data, and improve decision-making ability;

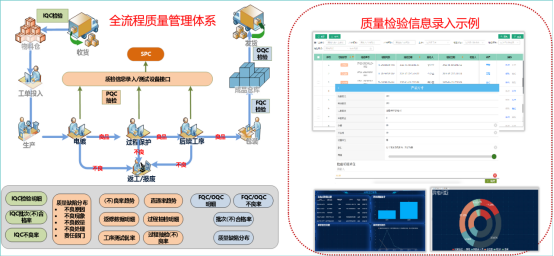

4. Implementing comprehensive quality control: digitizing inspection data and equipping it with statistical analysis tools for automatic analysis, forming quality status dashboards and SPC analysis dashboards, achieving comprehensive management of inspection work and quality traceability;

5. Implement cost control: Through multi-level BOM application, manage BOM usage and material quotas, compare actual usage with standard quotas, and implement inventory and consumption management for some precious metals involved in the production process.

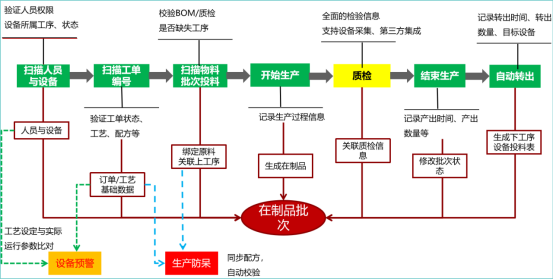

Main business process diagram

2、 Functional module: Comprehensive coverage of production management needs

1. Production Planning Management

The MES system can quickly generate accurate production plans based on market demand and sales orders. It not only supports the formulation of long-term plans, but also flexibly adjusts short-term production operation plans to ensure timely completion of production tasks. Through seamless integration with ERP systems, MES can obtain real-time order information and combine it with the real-time status of production resources to perform intelligent scheduling, optimize production processes, and improve production efficiency.

2. Material Management

Material management is crucial in electronic manufacturing. The MES system finely manages the entire lifecycle of materials, from raw material procurement and warehousing, to material requisition and issuance during the production process, and finally to inventory management of finished products, achieving precise control. By monitoring material inventory levels in real-time, MES can automatically trigger replenishment reminders to avoid production delays caused by material shortages. At the same time, the system can also trace the batch, supplier, and other information of materials to ensure their quality and compliance.

Figure Material Management

3. Production management

The MES system achieves full process tracking and control of production tasks through the production management module. MES can provide detailed data support from the issuance and execution of work orders to real-time feedback on completion status. Production personnel can perform operations such as scanning codes for feeding, parameter registration, and work reporting. Management personnel can check the progress of work orders at any time, promptly identify and solve problems that arise during the production process, and ensure that production tasks are completed on time and with high quality.

Production Management

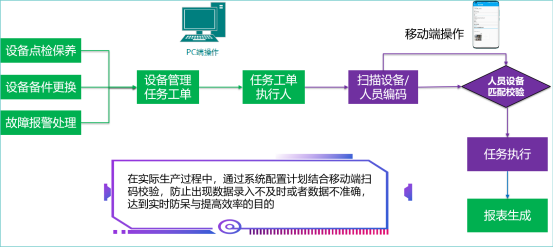

4. Equipment management

The efficient operation of electronic production equipment is the key to ensuring production quality. The MES system comprehensively manages production equipment, including equipment ledger management, maintenance plan formulation, fault alarm and handling, etc. By monitoring the real-time operation status of equipment, MES can predict equipment failures in advance, arrange preventive maintenance, reduce equipment downtime, and improve equipment utilization.

Image equipment management

5. Quality Management

In the electronics industry, product quality is the lifeline of enterprises. The MES system is equipped with a comprehensive quality management module, covering multiple stages such as raw material inspection, production process inspection, and finished product inspection. By collecting quality data in real-time, MES can quickly identify quality issues and trace them back to specific batches and production processes. The system also provides quality analysis reports to help enterprises continuously improve their quality control processes and reduce the rate of defective products.

Image Quality Management

6. Production data collection

The MES system utilizes advanced data collection technologies such as barcode scanning, RFID radio frequency identification, equipment interface communication, and the installation of sensors to collect various data in real-time during the production process. These data include material information, production progress, environmental temperature and humidity, equipment status, personnel performance, etc., providing accurate data support for production scheduling, material tracking, quality traceability, etc. Through data analysis, MES can help enterprises optimize production processes and improve production efficiency.

Image data collection

3、 Application scenario: Assisting electronic enterprises in efficient production

1. Production process optimization

In the production process of electronic products, MES system can monitor various production links in real time, timely discover bottlenecks and problems. For example, when equipment on a production line malfunctions or production progress lags behind, the MES system will automatically adjust the production plan and allocate tasks to other available equipment to ensure the continuity of the production process. At the same time, the system can optimize the production process based on production data, reduce unnecessary processes and waiting time, and improve overall production efficiency.

2. Quality traceability and improvement

For electronic products, quality traceability is crucial. The MES system achieves full traceability from raw materials to finished products by recording the production process data of products. When quality issues arise, companies can quickly identify the root cause of the problem and take corresponding measures for improvement. In addition, MES system can also analyze quality data to help enterprises identify potential quality risks, take preventive measures in advance, and improve product quality.

3. Supply chain collaboration

In the electronics industry, collaborative cooperation in the supply chain is crucial for the competitiveness of enterprises. The MES system can integrate with the supplier's system to achieve real-time sharing of material requirements. When the production plan of the enterprise changes, the MES system can automatically notify suppliers to adjust the material supply plan, ensuring timely supply of materials and reducing inventory backlog and stockout risks.

4、 Effect and Value: Enhancing the Core Competitiveness of Enterprises

1. Improve production efficiency

Through automated scheduling, real-time monitoring, and task allocation, MES systems can significantly improve production efficiency. Enterprises can reduce waiting time and human intervention in the production process to ensure efficient operation of every production link. According to statistics, the introduction of MES system can improve the production efficiency of enterprises by more than 20%.

2. Optimize resource allocation

The MES system maximizes the utilization of existing resources through comprehensive management and optimized configuration of production resources. Enterprises can track the real-time usage of resources, avoid resource waste, and reduce production costs. At the same time, the MES system can automatically adjust resource allocation according to production needs, ensuring the smooth completion of production tasks.

3. Improve product quality

The MES system effectively improves product quality through comprehensive monitoring and management of the production process. Enterprises can promptly identify and resolve quality issues in production, ensuring product consistency and high quality. Through the MES system, the defect rate of enterprises can be reduced by more than 30%.

4. Enhance corporate transparency

The MES system provides real-time production data and analysis reports for enterprises. Enterprise managers can keep track of production progress, quality status, equipment operation status, and other information at any time, achieving visual management of the production process. This helps businesses make quick decisions and improve operational efficiency.

5. Reduce operating costs

The MES system helps enterprises reduce operating costs by optimizing production processes, reducing resource waste, and improving production efficiency. Enterprises can reduce unnecessary inventory.