Electronic Ceramic Intelligent Manufacturing Revolution: How Hefei Hengli MES System Reshaps Industry DNA

Date:2025-09-16 Views:286

In the world of electronic ceramics, a thickness deviation of 0.1 microns may cause communication substrates to lose their 5G high-frequency performance, and a 1% fluctuation in oxygen content is enough to destroy millions of military sensor batches. As the global electronics industry accelerates towards 6G and third-generation semiconductors, Chinese electronic ceramic enterprises are facing unprecedented challenges: how to break free from the shackles of "master experience" in precision manufacturing? How to transform millions of production data into core competitiveness?

Breaking Moment: Industry Pains in the Digital Dilemma

Walking into any electronic ceramic factory, you can see such a scene:

The kiln operator adjusts the temperature curve based on experience, and the sintering defects are not exposed until 48 hours after the detection process

The customer urgently complained about abnormal dielectric constant, and the engineer spent three days searching through piles of paper records

Imported sintering furnaces, domestic printing machines, and testing equipment operate independently, and production scheduling meetings have become departmental game fields

Hengli Breakthrough: The Digital Transformation of Thirty Years of Kiln Genes

The transformation path of Hefei Hengli Equipment Co., Ltd. is a microcosm of industry upgrading. As a national high-tech enterprise incubated by the 43rd Research Institute of China Electronics Technology Group, Hengli has been deeply involved in electronic ceramic thermal equipment for 30 years, and its kiln equipment serves 70% of high-end ceramic enterprises in China. It is this profound understanding of process pain points that gave birth to the first full stack MES system in the electronic ceramic industry.

At the CITE exhibition in Shenzhen in 2025, the Hengli booth was surrounded and packed. Real time data from a factory thousands of miles away is jumping on the big screen: at the moment when the temperature curve of a furnace on a car grade aluminum nitride substrate production line in Anhui deviates from the standard value by more than ± 3 ℃, the system automatically triggers an alarm and adjusts the atmosphere concentration. This is exactly what the three core engines of Hengli MES are working on:

1、 Deep interconnection of process equipment: making the "black box" transparent

Kiln nerve center: Directly connected to 32 temperature zone sensors inside the kiln through SCADA system, real-time monitoring of temperature field uniformity

Rebirth of old equipment: adding protocol conversion module to imported press machines in the 1990s, with a pressure curve digitization rate of 100%

Error prevention mechanism: automatic verification of printing alignment parameters, incorrect settings cannot start the device

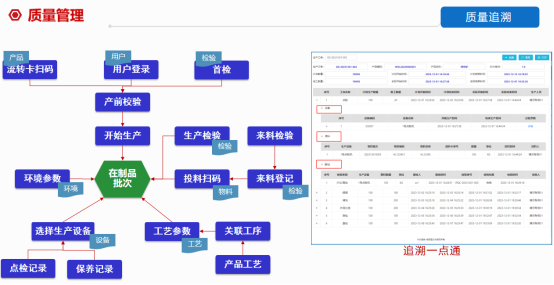

2、 Full link quality closed-loop: Implanting 'digital genes' into each ceramic piece

SPC prediction system: implement millisecond level monitoring of warpage, automatically identify abnormal trends and locate them to specific kiln sections

Lightning tracing: Scan the finished product QR code and display the entire chain data of powder batch → sintering curve → testing report within 2 minutes

Closed loop improvement: Linking metalization delamination defects with oxygen content fluctuations to drive process optimization

3、 Flexible production center: solving the dilemma of multiple varieties and small batches

Dynamic Scheduling Engine: Intelligent insertion of pre burning tasks based on kiln cooling curve, increasing line changing efficiency by 40%

Digital Twin Preview: Simulating the Impact of Process Changes on the Production Line, Reducing Trial and Error Costs by 65%

Intelligent material linkage: Real time synchronization of workshop consumption data with warehouse system, shortage warning 4 hours in advance

Practical achievements: The digital rebirth of multiple domestic ceramic enterprises, and the transformation of a domestic new energy vehicle ceramic parts manufacturer after introducing the Hengli MES system:

Quality loss reduced by 35%: By capturing real-time fluctuations in oxygen content in the sintering zone, we can avoid metalization delamination of 12 batches of products throughout the year;

Traceability efficiency improved by 90%: the full process data packet generation time required for customer review has been reduced from 8 hours to 30 minutes;

Comprehensive and intuitive data display to improve decision-making ability: Real time monitoring of production status, equipment status, and other information through reports and dashboards to achieve production transparency.

Dual genes: Why MES that understands processes cannot be replicated

The moat of Hengli MES originates from its unique industrial DNA double helix:

Process knowledge base: 30 years of kiln research and development data, built-in LTCC/MLCC/PTC and other 200+process templates

Military grade adaptation: The modular architecture supports both 10000 square meter factories and 10 person small lines in research institutes

Autonomous and controllable kernel: Multiple software works build security barriers to meet the encryption requirements of military clients

Ecological Symbiosis: Co building a Ceramic Technology Database with China Electronics Technology Group Corporation to Continuously Feed Algorithm Optimization

Pure software companies do not understand the distribution of furnace thermal fields, and equipment manufacturers lack system integration capabilities, "Hengli technicians pointed out at a technical seminar." And we need to master both equipment language and data language at the same time, which is the key to breaking through the situation

Future battlefield: When MES becomes the central nervous system of the industry

Faced with the precision requirement of 0.01mm for 5G millimeter wave devices and the 0.2% expansion coefficient fluctuation of semiconductor packaging substrates, Hengli is upgrading MES to an industrial grade operating system:

Digital twin: Real time mapping of kiln physical state, prediction of refractory material life, and triggering preventive maintenance

AI process optimization: training sintering parameter models based on historical data, improving yield and entering the era of "autonomous driving"

Industrial Chain Blockchain: Connecting batch data from powder manufacturers with testing results from packaging factories to build a quality collaborative network

The intelligent manufacturing revolution of electronic ceramics began with the digital genes of each substrate and evolved into intelligent control of each sintering process. When traditional factories transform into self optimizing life forms, Chinese manufacturing is writing a new industrial narrative.