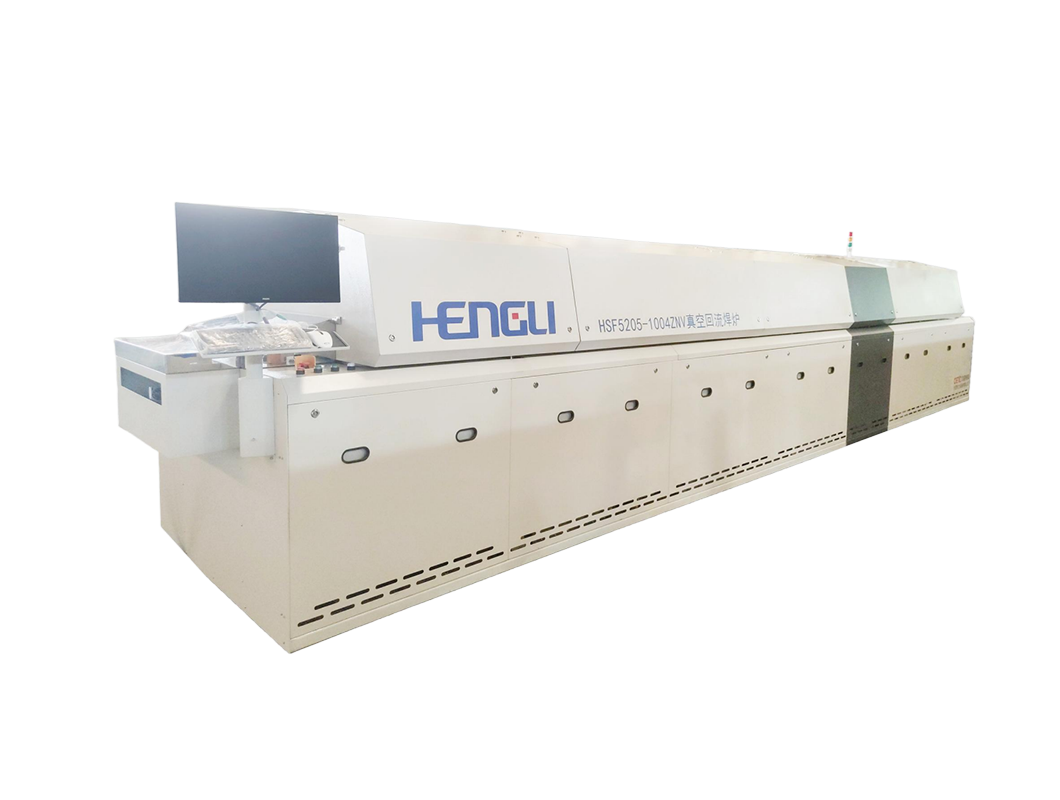

An advanced reflow soldering equipment designed to meet the "void-free" solder joint requirements in electronics manufacturing, particularly in power electronics and high reliability applications. Utilizes vacuum technology to significantly reduce void rates (≤2%), widely applied in high quality welding scenarios for precision components in laser devices, aerospace, electric vehicles, etc.

Designed with multiple zones and single/double track transmission. The vacuum chamber roller hearth requires no lubrication for easy maintenance. Mid-wave radiation heating ensures precise temperature profiling for soldering quality. Quick disconnect vacuum modules enhance machine availability. Meets SMT high density soldering requirements and large thermal capacity module assembly, with uniform temperature control. Flux exhaust uses a cracking catalytic filtration system for reliable operation.

| Series | Adjustable Width of Track | Chamber Height | Max Temp | Zone Length | Heating Zone | Atmosphere |

| HSF | 100-500mm | 60mm | 400℃ | 350mm/420mm | 7-12 | N2/Air/Vacuum |