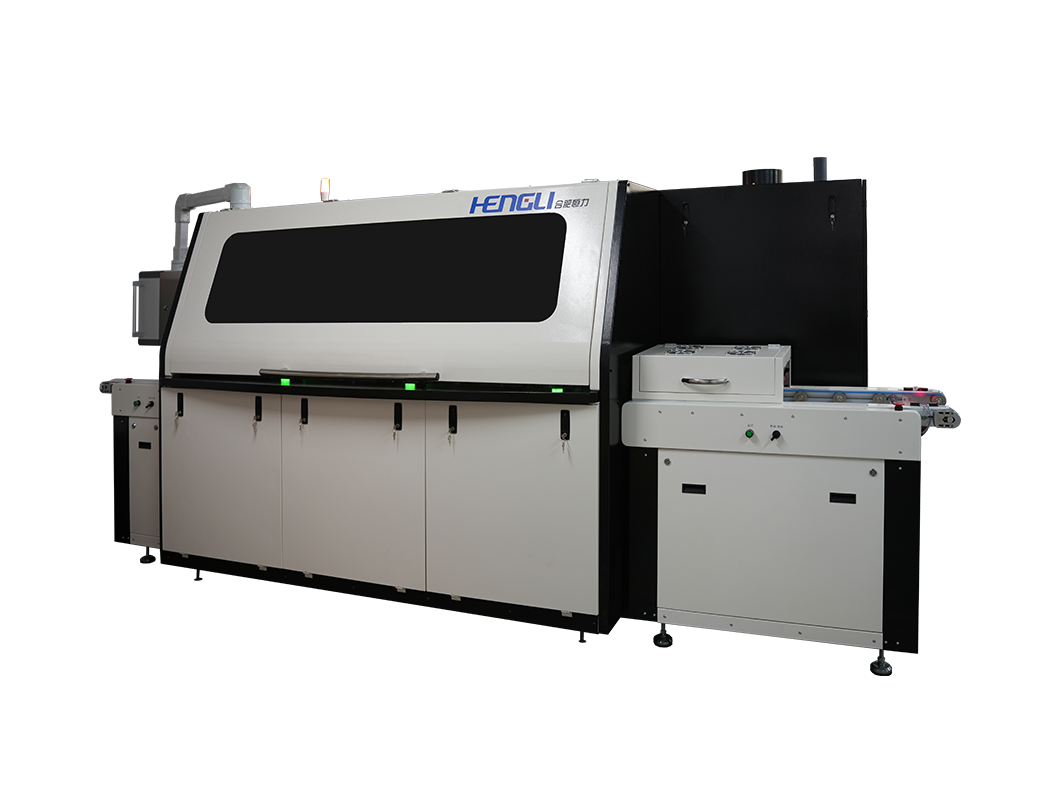

Designed with preheating, heating and cooling zones in independent process chambers, suitable for power semiconductors (IGBT modules, MOSFETs), microelectronics hybrid assembly, optoelectronic packaging, hermetic packaging, wafer-level packaging, UHB LED packaging and MEMS packaging.

Integrated with N₂/formic acid/H₂ composite atmosphere system. Digital mass flow controllers (MFCs) enable dynamic adjustment of gas ratios (formic acid concentration control accuracy ≤±3%), compatible with both solder sheet processes and gaseous flux collaboration. Equipped with full process formic acid safety management system, including gas pressure adaptive compensation, online concentration monitoring, and tail gas condensation recovery unit, ensuring emission control and recycling. Supports custom profile programming, suitable for precision manufacturing of IGBT chip eutectic bonding, high-density power module packaging, SiC pressureless silver firing, etc., applied in new energy vehicles, photovoltaic inverters, and other high-voltage high-power device manufacturing.

| Series | Number of Cavity | Vehicle Size | Effective Height | Ultimate vacuum | Max Temp | Atmosphere |

| HL-V100/300/400 | Single/Three/Multiple | 410*280mm | 100mm | 10Pa | 450℃ | HCOOH/N2/H2/Vacuum |