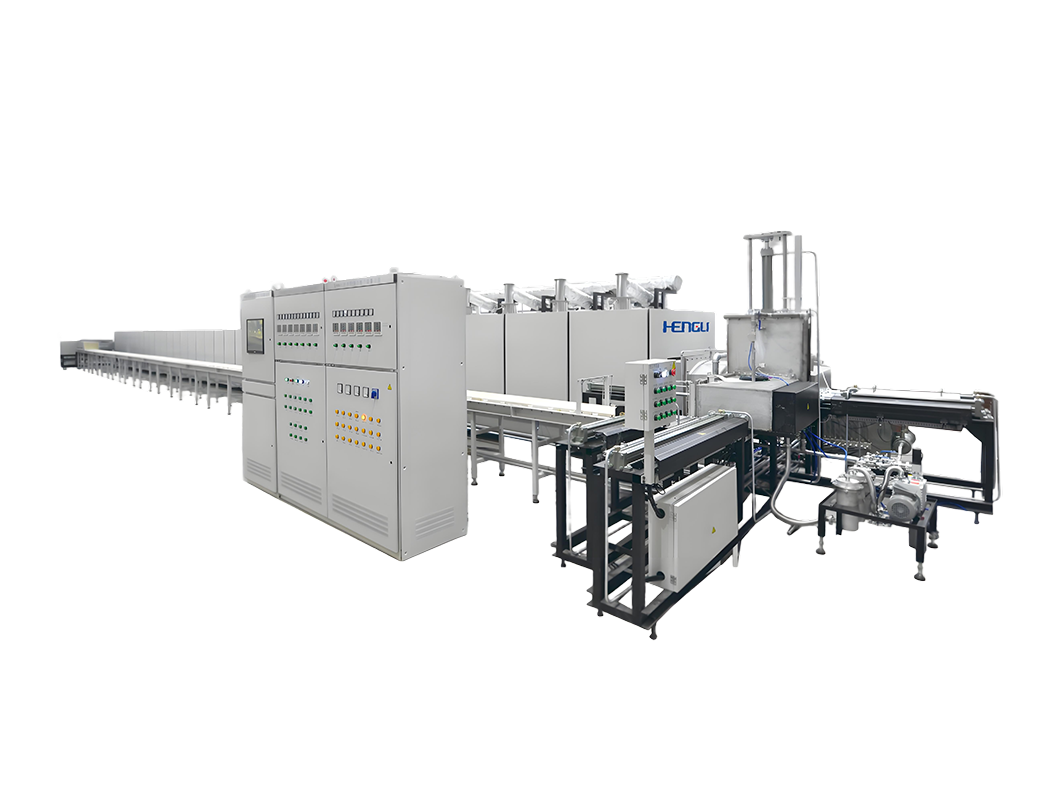

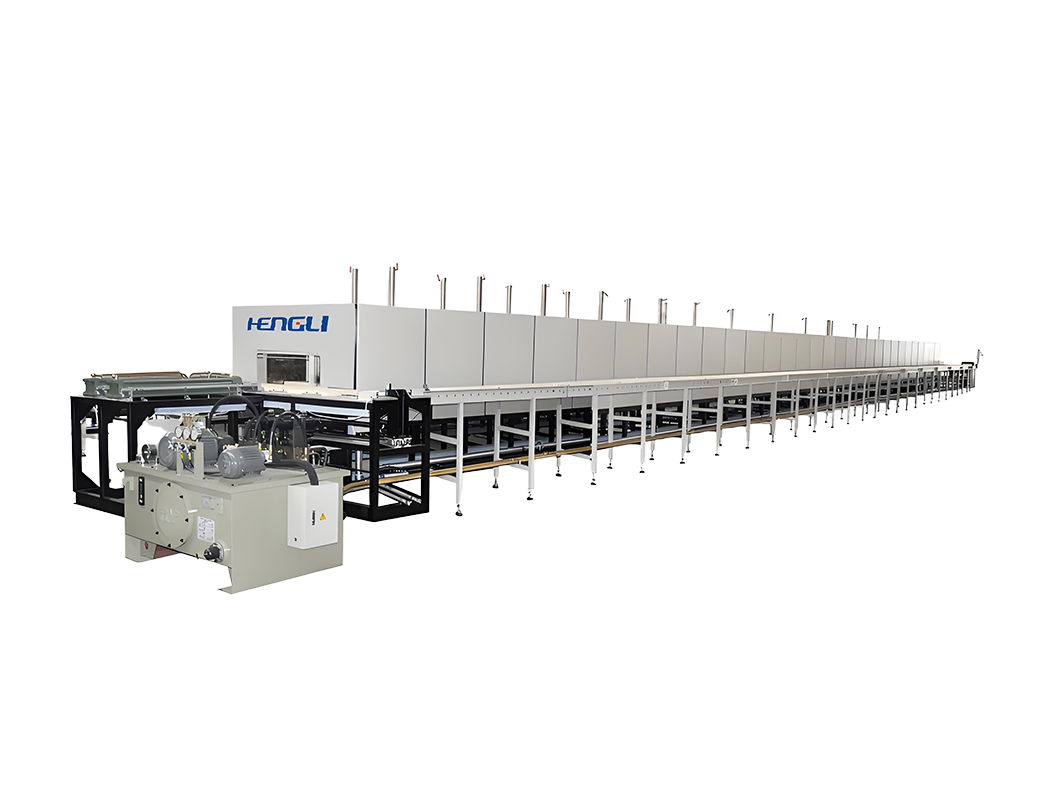

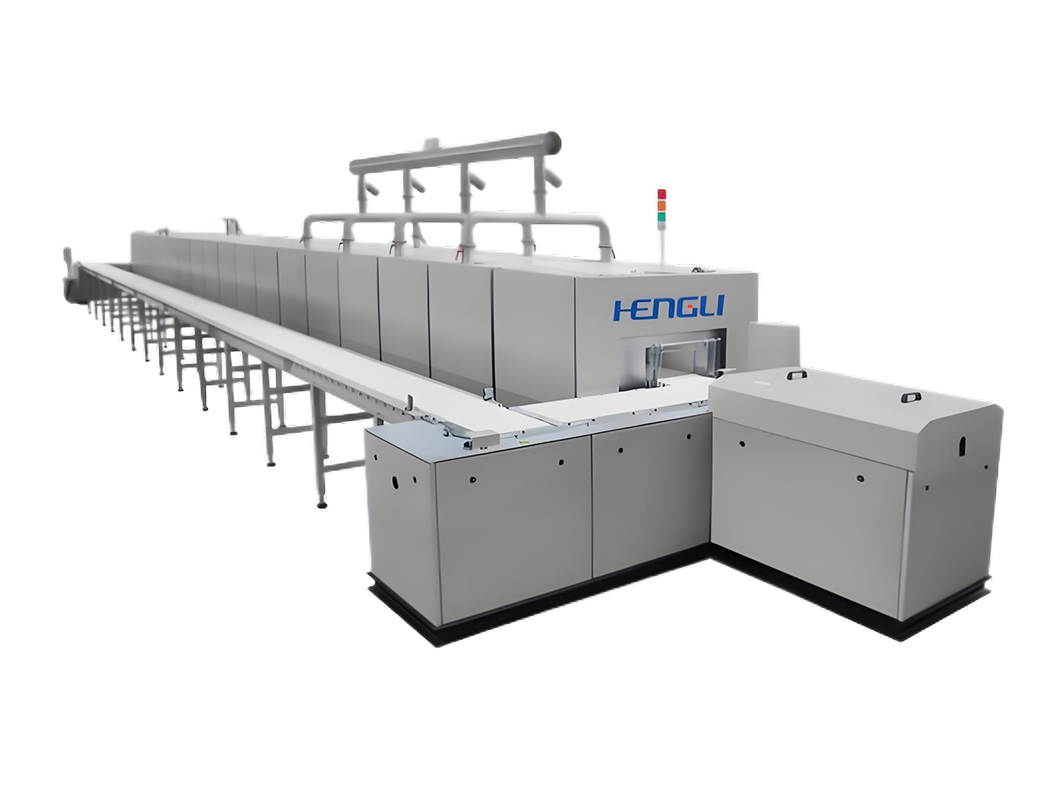

Specialized for heat treatment processes of strontium titanate varistors, MLCC, magnetic materials, lithium battery anode/cathode materials, solid electrolytes, rare earth materials, hard carbon, silicon-carbon anodes and activated carbon materials under protective atmospheres.

Adopts a high-sealing structure with a displacement chamber of internal and external sealing doors, ensuring that the oxygen content in the furnace remains unaffected during material loading and unloading. The chamber uses a corrosion-resistant heavy-duty material vaulted roof to facilitate exhaust gas discharge. Heating elements are protected by quartz tubes or corundum tubes to prevent corrosion from gummy atmospheres. Pre-firing and firing functions can operate independently or integrate debinding-sintering processes.

| Series | Pusher Size | Effective Height | Max Temp | Zone Length | Heating Zone | Atmosphere |

| HTF/HTD/HTL | 200-500mm | 50-400mm | 1200/1400/1650℃ | 300-2000mm | 8-20 | Air/N2/O2/H2/Ar |