In Hengli's intelligent SMT production workshop, the new scene is truly remarkable: dozens of high-precision pick-and-place machines precisely place tiny components onto PCB boards at a dizzying speed, while in the reflow oven, circuit boards carrying the "soul" of intelligent devices are undergoing a precise heat treatment process... On the intelligent monitoring screen in the center of the workshop, the production status of each board, the quality data of each placement point, and the operating parameters of each device are all updating in real-time - behind this is the dedicated MES system developed by Hengli after more than a decade of deep involvement in the PCBA industry, playing the core role of the "digital brain".

1. The Urgent Need for Digital Transformation in the PCBA Industry

With the rapid development of technologies such as 6G, the Internet of Things, and artificial intelligence, the PCBA industry is facing unprecedented opportunities and challenges. The continuous shortening of the product lifecycle of electronic products, the increasing number of personalized demands, and the increasingly stringent quality requirements are all forcing manufacturing enterprises to carry out digital transformation and upgrading. The challenge of refined control in SMT production lines has always troubled industry practitioners. The quality risks brought by high-density component placement are becoming increasingly prominent, and the popularization of small-sized components has made traditional manual inspection methods unsustainable. The wide variety of materials leads to difficulties in traceability, with a single product involving up to hundreds of types of materials. Any material errors or mixing can cause significant losses. The improvement of Overall Equipment Effectiveness (OEE) has hit a bottleneck, and expensive imported equipment struggles to achieve maximum efficiency. The optimization of process parameters lacks data support, and engineers often rely on experience rather than scientific data to make decisions.

2. Comprehensive Solutions Deeply Aligned with PCBA Manufacturing

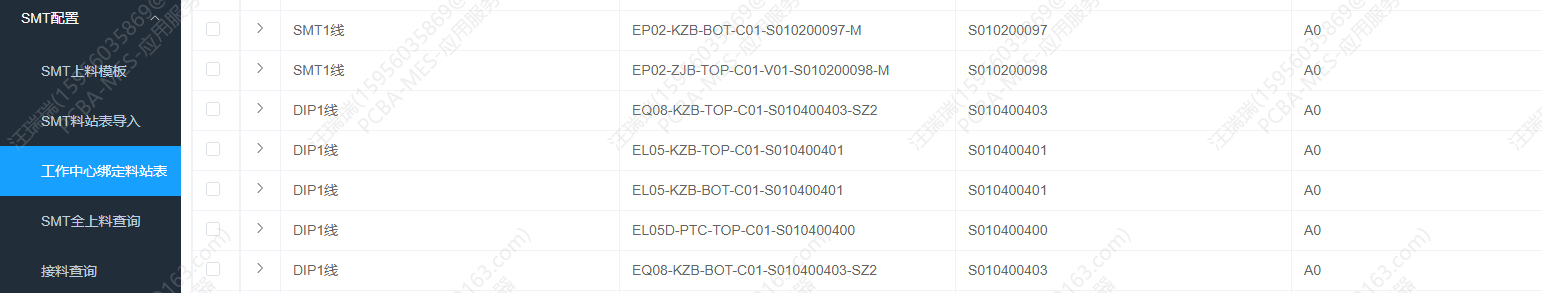

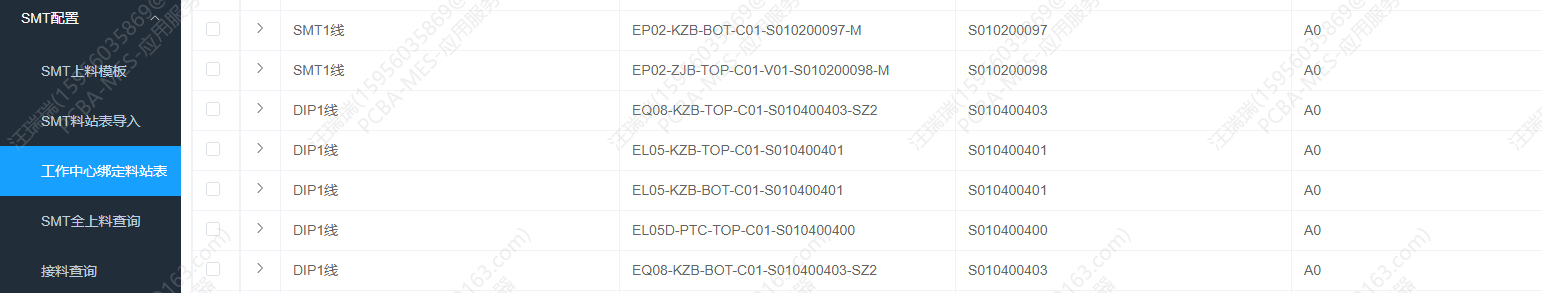

Based on a profound understanding of industry pain points, Hengli has invested in a R&D team and spent three years developing an intelligent MES system specifically tailored to the PCBA industry. This system has achieved breakthrough digital management and control in all key links of the SMT production line. The intelligent material loading error prevention mechanism is the first major highlight of the system. Through in-depth connection with the placement machine, the MES system can automatically verify the consistency between material positions and program settings. During the production of an important customer's automotive electronics order in the first half of this year, the system successfully intercepted 5 risks of material errors, including 3 risks of material errors for ultra-small-sized components, avoiding potential losses of hundreds of thousands of yuan.

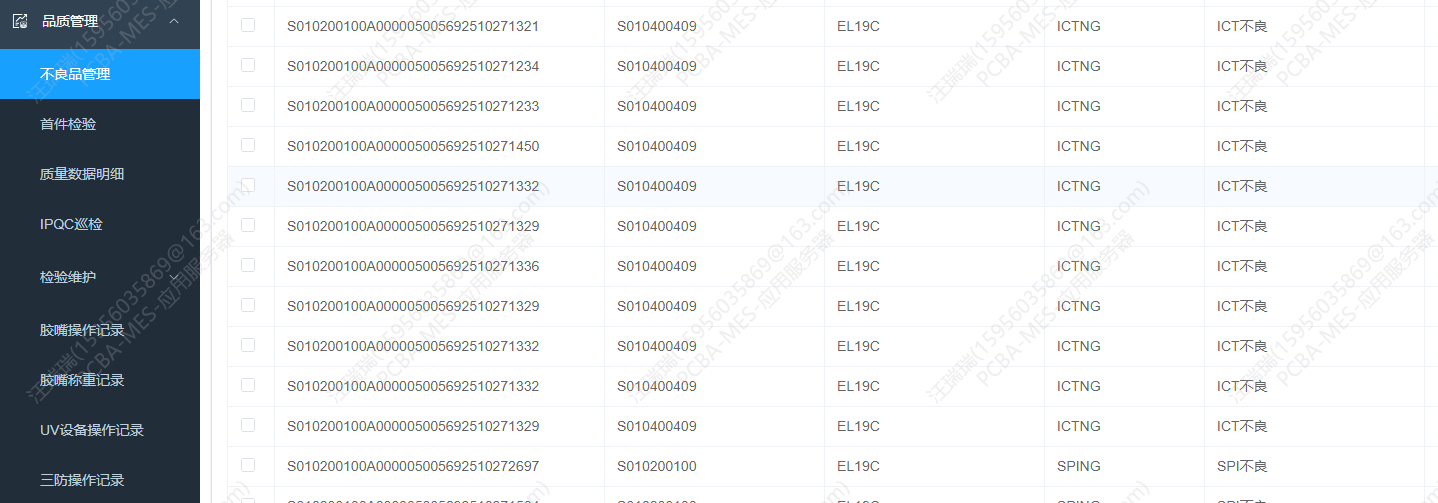

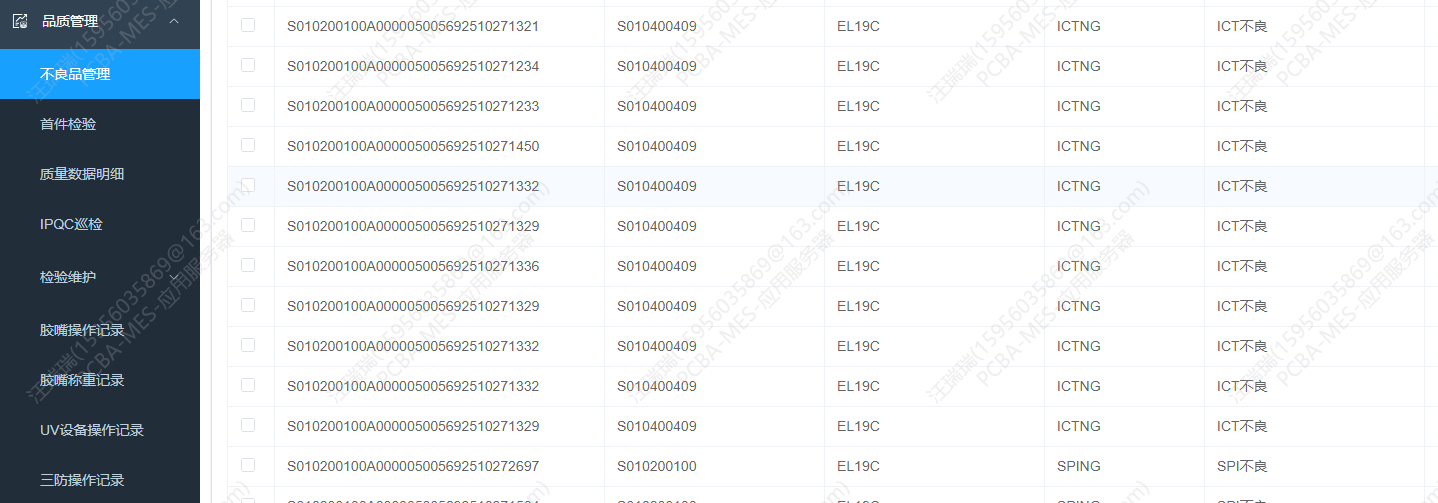

The full-process quality traceability system has established a complete data chain. From the thickness parameters of solder paste printing, the component rejection data of pick-and-place machines, to the furnace temperature curve of reflow soldering and the test results of inspection equipment, every key process parameter is collected, monitored, and analyzed in real time. When soldering defects occur, quality engineers can accurately locate the root cause of the problem within 5 minutes, whereas in the past, this process often took more than 2 hours. In the third quarter of this year, through this system, Hengli's MES system successfully increased the First Pass Yield from 92% to 97.8% and reduced the complaint rate by 43%. The Equipment Efficiency In-depth Analysis System provides a scientific basis for continuous improvement. The system automatically collects and analyzes 28 key indicators such as the rejection rate, pick-up rate, placement accuracy, and equipment utilization rate of pick-and-place machines, and provides optimization suggestions through big data analysis. After deploying the system, a certain customer increased the overall equipment efficiency from 63% to 86%, reduced material loss alone by 18%, and saved more than 400,000 yuan in costs annually.

3. Comprehensive Leap from "Manufacturing" to "Intelligent Manufacturing"

In the digital factory built by Hengli, the changes brought about by the MES system are reflected in every detail.

Digitalization of ticket management makes production planning more accurate and efficient. Electronic tickets are issued in real-time to each workstation, ensuring transparent

and controllable production progress. Refined Material Management has achieved comprehensive material control. From material trays, Feeders to Nozzles, every material and related accessories have implementedfull lifecycle management. Preemptive quality control eliminates quality issues in their infancy. By monitoring key process parameters in real-time, the system can instantly detect anomalies, issue instant alarms,

and handle them immediately during the production process.

4. Building the Digital Foundation of the PCBA Industry

The success of the Hengli Intelligent MES system is inseparable from its advanced technical architecture design. The system adopts a microservice architecture, featuring high flexibility and scalability: The Data Acquisition layer supports multiple interface protocols and can seamlessly connect with devices of different brands and models. Whether it is a pick-and-place machine from Siemens or Fuji, or a reflow oven from HELLER or BTU, stable and reliable data acquisition can be achieved. The Central Product Platform layer sediments the professional knowledge of the PCBA industry into reusable business components. From stencil management, feeder calibration to equipment maintenance and process optimization, each business scenario has a corresponding standardized module. The Data Analysis layer deeply mines the value of data. Advanced functions such as intelligent early warning, parameter optimization, and quality prediction provide intelligent support for production management. The application ecosystem layer supports personalized customization and secondary development, ensuring that the system can adapt to the specific needs of different enterprises. At the same time, it provides open API interfaces to facilitate integration with the enterprise's existing ERP, WMS, and other systems.

5. A New Chapter in Intelligent Manufacturing of the PCBA Industry

With the advent of the Industry 4.0 era, intelligent manufacturing in the PCBA industry will develop towards greater intelligence, flexibility, and greenness. Hengli is actively planning the R&D of a new generation of MES system: The application of digital twin technology will enable real-time mapping between the physical factory and the virtual factory, and proactively identify and resolve potential issues in the production process through simulation optimization. The AI quantity prediction system will achieve early identification and early warning of quality risks through deep learning algorithms, shifting quality management from post-processing to pre-prevention. The self-adaptive production system will automatically adjust production process parameters based on parameters such as equipment status, material characteristics, and environmental conditions, realizing "unmanned" intelligent decision-making. The industrial chain collaboration platform will connect the entire process data chain from design to manufacturing, achieve collaborative optimization of design and manufacturing, and significantly shorten the new product introduction cycle.