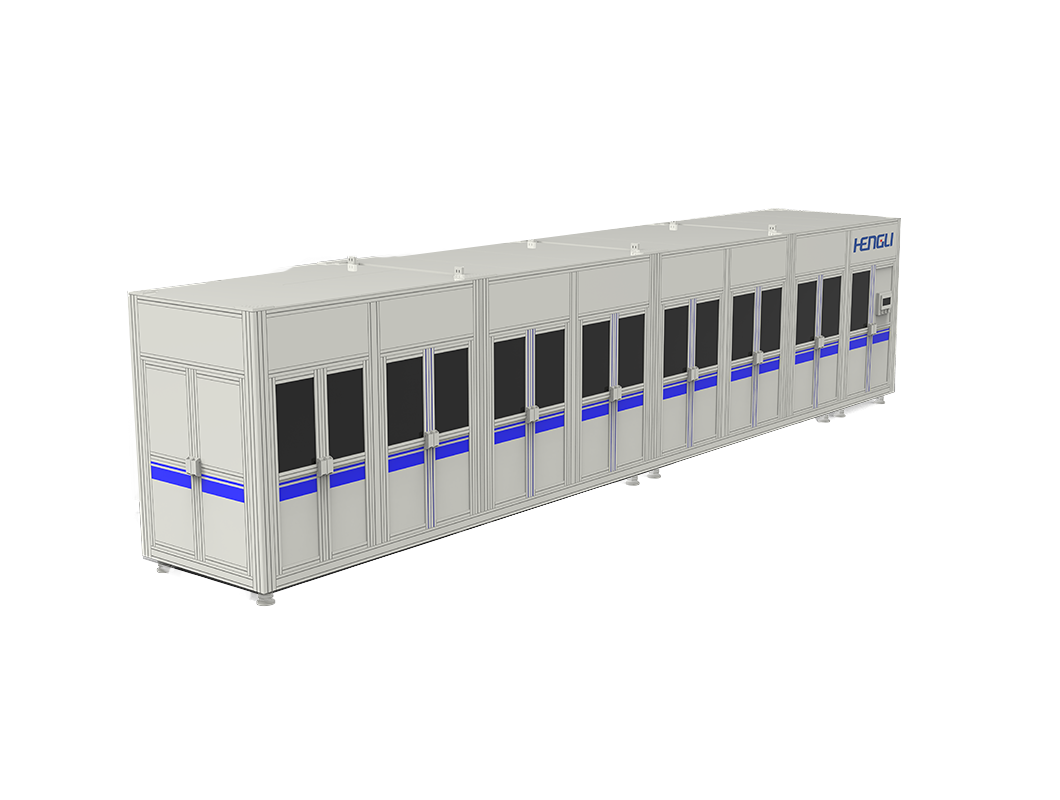

Layered Annealing Crystallization Furnace

Adopts self-developed heating system and temperature control method to improve thermal uniformity during perovskite crystallization, ensuring consistency in rapid annealing and crystallization of perovskite materials.

Options:

Perovskite, layered annealing, crystallization, independent temperature control, rapid cooling, ultra-clean environment, industrial computer, touch screen

Product Feature

Product Details

| Series | Product Size | Loading Direction | Max Temp | Takt Time | Heating Zone | Atmosphere |

| HXL | 300×300mm-2400×1600mm | Long edge loading | 200℃ | ≥30s/PCS | Pre-heating/heating/cooling zones | Air/Vacuum |

Do you want to learn more/collaborate with me?

It is the long-term support, understanding, and trust of our customers and friends towards Hengli that has enabled us to move forward with unparalleled passion and persistence on the path of intelligent manufacturing and green development. If you want to learn more about Hengli, please feel free to contact us.

0551-65846903