Used for heat treatment processes of piezoelectric, varistor, thermistor, magnetic and electronic ceramic materials under air atmosphere, as well as firing, oxidation-reduction, annealing, normalizing, quenching, tempering, solution treatment, preheating, and debinding of strontium titanate, MLCC, lithium cathode/anode materials, rare earths, silicon-carbon composites and activated carbon under reducing atmosphere.

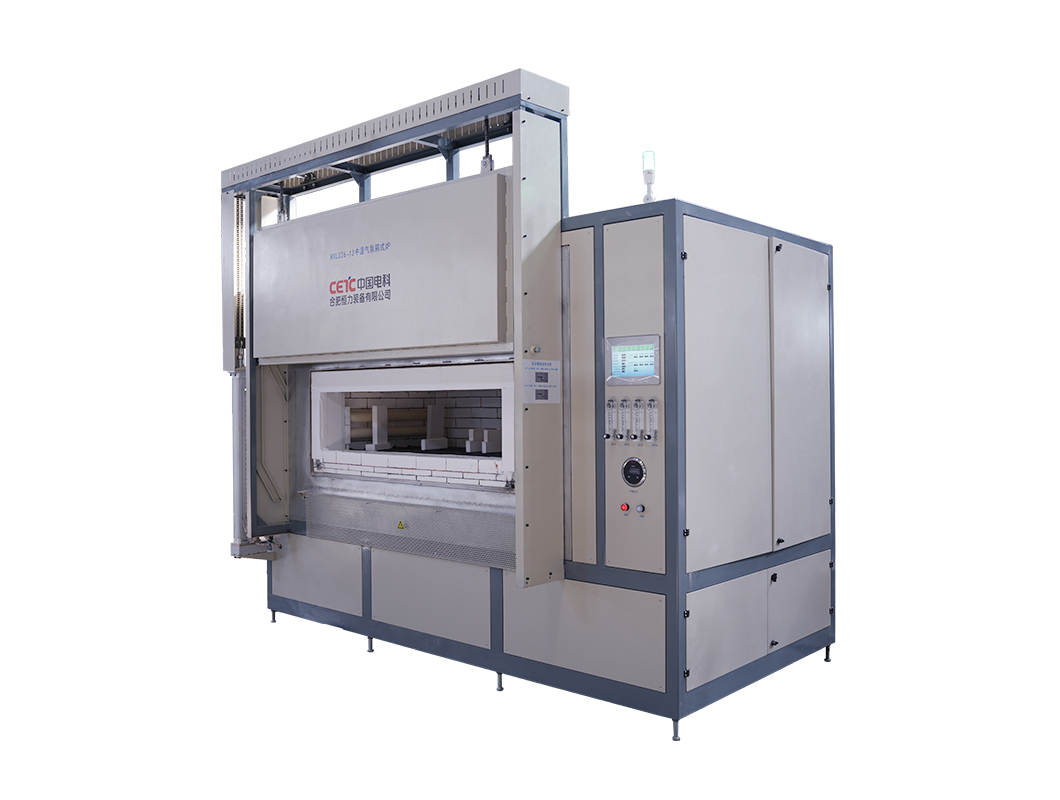

Also known as muffle furnace, it adopts ceramic fiber (alumina) chamber with excellent heat preservation, high strength and energy-saving efficiency. The oven top features a reinforced composite structure to prevent collapse after long-term use. Heating elements include FeCrAl resistance wires, silicon carbide rods and silicon molybdenum rods, etc., enabling a wide temperature control range and compatibility with various atmospheres.

| Series | Effective Volume | Heating Element | Max Temp | Chamber Depth | Heating Zone | Atmosphere |

| HXL | 20-1000L | FeCrAL/silicon carbide rods/silicon molybdenum rods, etc. | 1700℃ | 400-1000mm | Single/Multiple | Air/N2/O2/H2/Ar |