After perovskite solution coating, rapid vacuum pumping evaporates part of the solvent to form a film, followed by annealing to optimize crystallization.

The perovskite flash evaporation furnace leverages the principle that when a high-pressure, high-temperature liquid enters a low-pressure environment, its temperature exceeds the boiling point at the new pressure, causing instantaneous vaporization. This process utilizes the property that the boiling point of a substance decreases with pressure reduction. As the solution is depressurized, solvent molecules rapidly vaporize, absorbing latent heat of vaporization, which achieves the effect of rapid vacuum-driven solvent evaporation after coating.

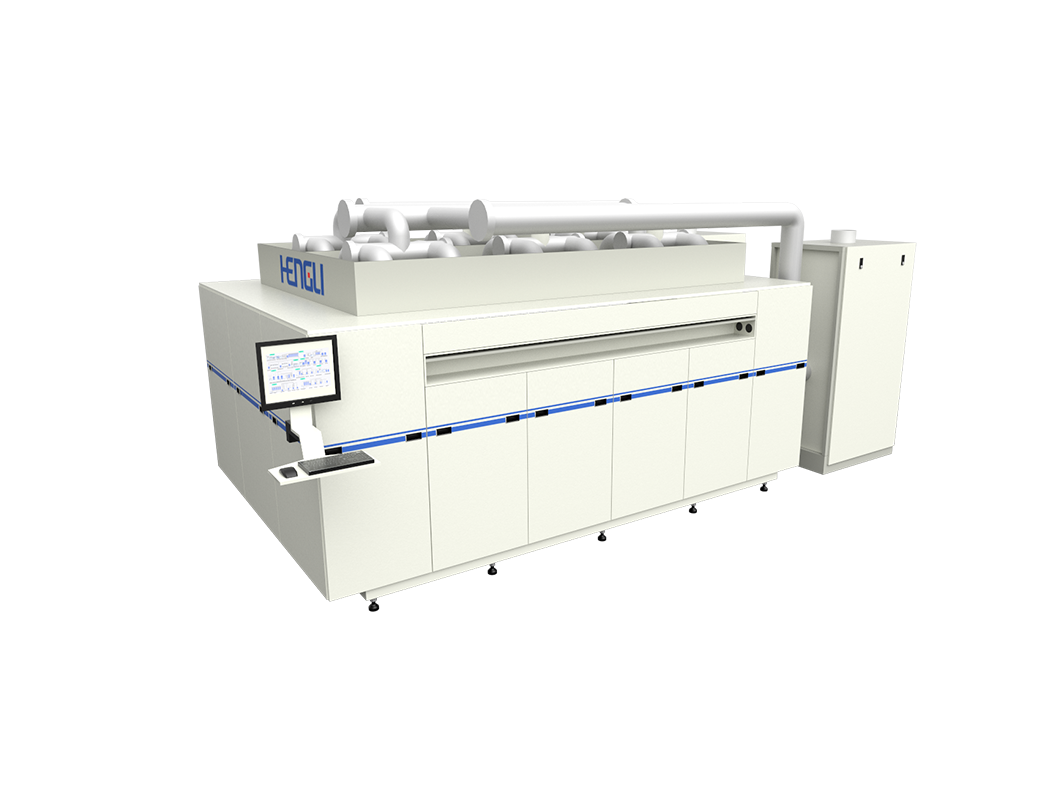

| Series | Product Size | Substrate Thickness | Pumping Speed | Zone Length | Substrate State Temp | Atmosphere |

| HVT | 2400mm×1200mm | 1.6-3.2mm | Reach 10Pa within 10s | 3000mm | 20-150℃ | Air/Vacuum |