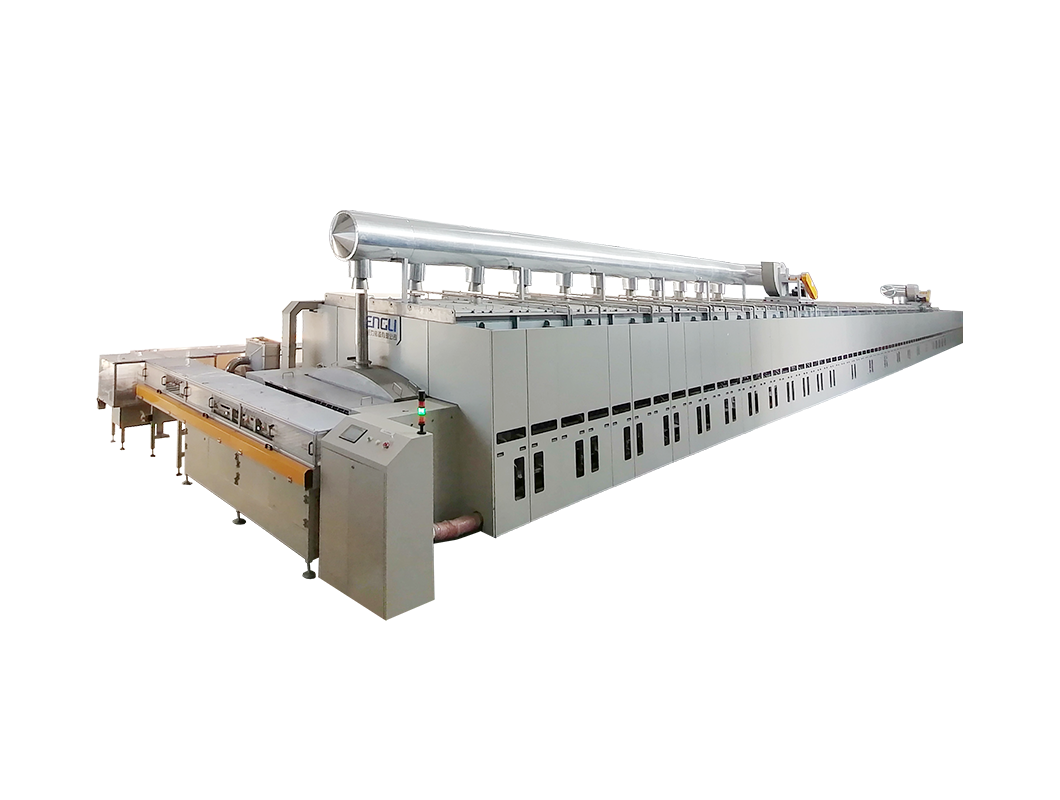

Mainly used for pre-firing and firing heat treatment of electronic ceramic powders, ceramic substrates, MLCC ceramics, magnetic materials, etc.

Designed with an integrated debinding-firing structure to reduce process switching and improve efficiency. Equipped with adjustable heating rates and exhaust volume to ensure complete decomposition of organic substances (e.g., PVB resin, DOP) during debinding, preventing firing delamination or cracking. It covers 1100℃-1300℃, meeting pre-firing and firing requirements for aluminum nitride substrates, MLCC ceramics, etc., while supporting integrated debinding-firing for tape-cast substrates; adapts to differentiated temperature settings for Ni/Cu electrode materials and high-temperature pre-firing of magnetic materials to optimize properties and supports debinding-firing of functional ceramics like silicon nitride and dielectric ceramics.

| Series | Chamber Width | Effective Height | Max Temp | Zone Length | Heating Zone | Atmosphere |

| HGF | 400-1360mm | 50-260mm | 1350℃ | 450mm/600mm/750mm | 8-25 | Air/N2/Ar/H2, humidification N2/H2 |