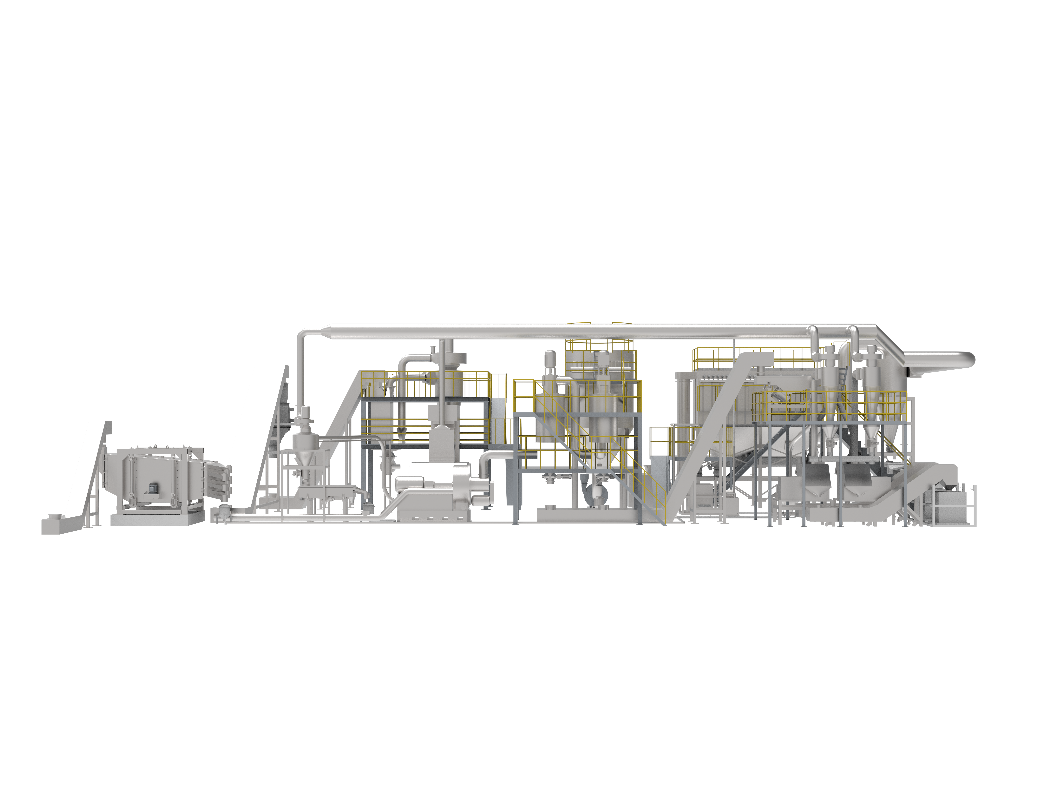

After battery crushing materials or electrode sheets enter sorting system, efficient dissociation and recovery of metals and non-metallic substances are achieved through multi-stage physical collaboration of "crushing-screening-sorting". The core of this system lies in the linkage of particle size classification and sorting technologies to maximize material value release while balancing environmental protection and cost-effectiveness.

1. Integrated sorting technologies (magnetic separation → air classification → specific gravity sorting): Magnetic separation removes ferromagnetic impurities; vertical air classification separates light copper-aluminum foils/powders from heavy metal casings; vibrating shaking table performs specific gravity sorting to precisely separate metals with similar particle sizes (e.g., copper/aluminum) and non-metallic residues.

2. Multi-stage physical dissociation (primary crushing + fine grinding): mechanical forces gradually break the adhesive structure between metals and non-metals in battery materials, releasing copper foils, aluminum foils, cathode active materials, graphite, etc.

3. Multi-stage screening collaboration: multi-stage screening controls material particle size step-by-step and filters battery electrode powders to optimize sorting efficiency.

| Indicator | Capacity | Installed Power | Black Powder Recovery | Copper & Aluminum Content | Copper & Aluminum Recovery Rate | Copper & Aluminum Recovery Purity | PM Emission |

| Parameter |

Plate 0.5-2t/h, Battery crushing material 0.5-2.5t/h |

300-600kW | ≥98% | ≤1% | ≥98% | ≥95% | <20mg/m³ |