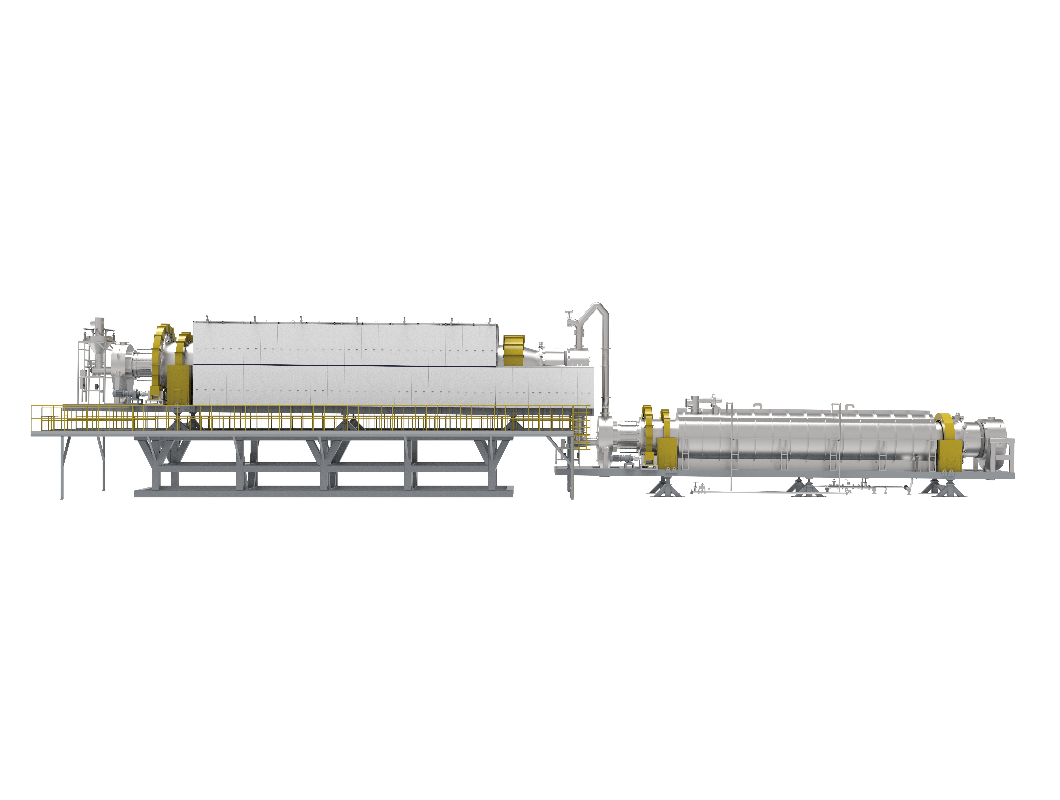

Aiming at the special needs of lithium battery recycling industry, the rotary furnace has been optimized and upgraded in several key technical aspects such as material propulsion and conveying, sealing performance and corrosion resistance.

1. Stable and efficient material propulsion and conveying capacity ensures the stability of pyrolysis time.

2. Multi-stage sealing technologies including packing, end face and air ring effectively improves the sealing performance of the rotary kiln.

3. Preposed electrolyte volatilization, reliable sealing and corrosion-resistant composite materials enhances corrosion resistance and extends the service life.

| Indicator | Furnace Tube Diameter | Capacity | Temperature | Oxygen Content | Temperature | Installed Power | Operation Power | Heating Method | Discharge Temp |

| Parameter | 400-2800mm |

Plate 0.2-1.5t/h, Battery 0.3-2.5t/h |

200-900°C |

≤50ppm(N2 source 99.999%) ≤1%(N2 souce 99.9%) |

±5°C | 200-1500kW | 100-800kW | Electricity/Natural gas | ≤80°C |