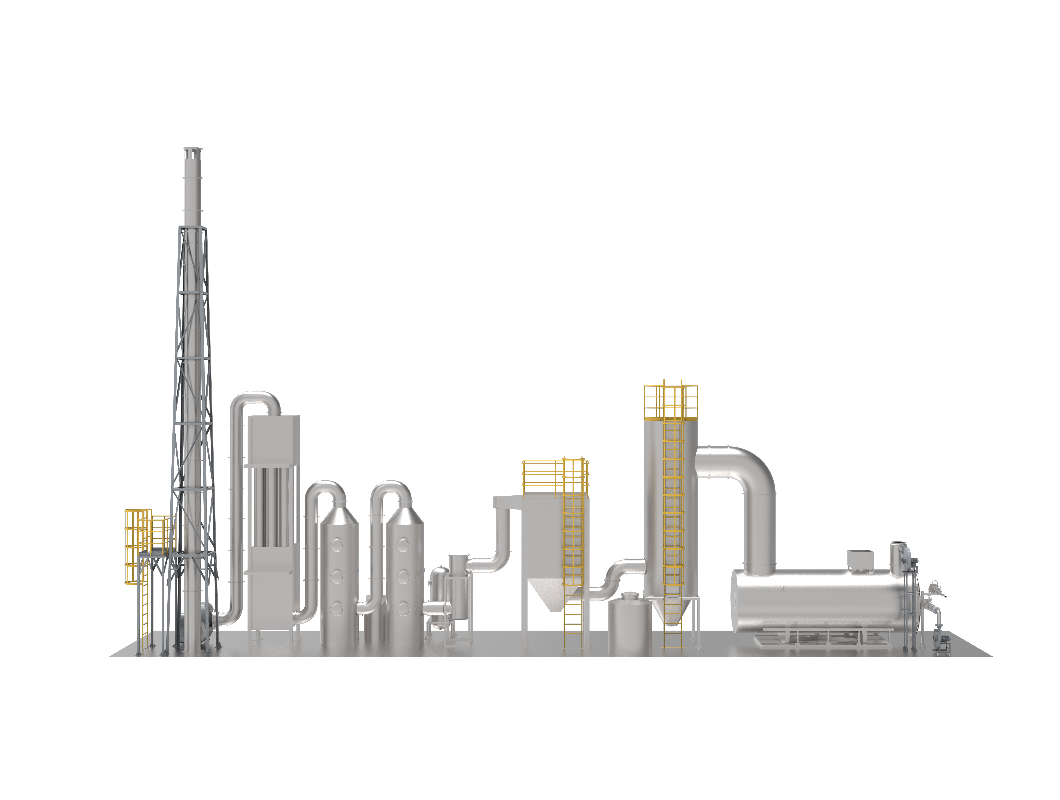

Exhaust gases from crushing-drying, electrolyte, and pyrolysis enter TO furnace through separate pipelines. After combustion, they undergo rapid cooling, bag dust removal, multi-stage neutralization spraying (2-4 stages), and wet electrostatic precipitation before being discharged with high-altitude make-up air.

1. Large-air-volume TO furnace design ensures waste gas residence time exceeds 2 seconds, enabling stable and thorough treatment. The chamber uses corundum material for corrosion resistance;

2. TO furnace exhaust immediately contacts atomized liquid water in the quenching tower, rapidly reducing flue gas temperature to prevent re-formation of dioxins;

3. Electrolyte (liquid/gas) from the crushing-drying process serves as fuel, saving natural gas consumption (nearly no need for supplementary natural gas during continuous stable operation);

4. Wet electrostatic precipitator captures mist droplets and other pollutants in flue gas, preventing white fog in exhaust and fluoride entrainment that could cause emission exceedances.

| Indicator | Air Volumn | VOCs Emission | Fluoride Emission | PM Emission |

| Parameter | 1000-4000Nm³/h | <40mg/m³ | <3mg/m³ | <20mg/m³ |