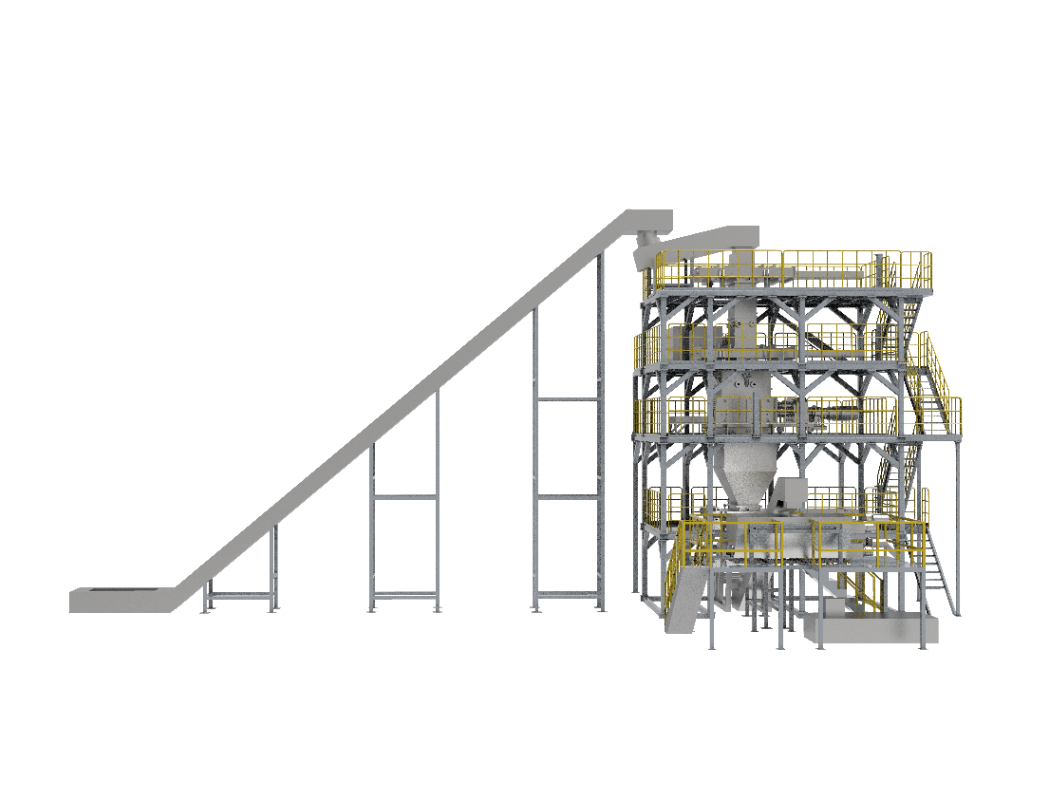

Charged NCM/LFP batteries are quantitatively fed into the crushing and drying system via a conveyor. The system is vertically structured with a replacement chamber, crushing chamber, buffer chamber, and vacuum dryer. Batteries pass through each functional chamber in a step-by-step manner to complete crushing and electrolyte drying. The stepping process includes atmosphere replacement and pressure balancing to ensure safe crushing of lithium batteries.

Exhaust gases generated during crushing and drying contain dust and electrolyte. After dust filtration and electrolyte gas-liquid separation, they enter the TO combustion treatment in two forms.

1. The four axis primary crusher offers higher crushing efficiency than traditional two-stage crushing (double axis + single axis), saving space with a smaller internal volume for easier control of sealing and pressure.

2. Drying under vacuum conditions ensures high efficiency and electrolyte removal rate, facilitating centralized treatment without odor.

| Indicator | Application |

Crushing Form

|

Fragmented Drop Size

|

Capacity

|

Crusher Power

|

Pressure Control System Power

|

Safety Monitoring

|

Heating Method of Vacuum Drying System

|

Vacuum Drying Temperature

|

| Parameter |

1000×500×500mm(L×W×H) NCM/LFP cell or module

|

Four axis primary crusher

|

12-25mm

|

0.5-2t/h (LFP battery)

0.5-1t/h (NCM battery)

|

22×2kW-37×2kW

|

22×4kW-37×4kW

|

Oxygen content, pressure, temperature, flame, etc

|

Steam/Thermal oil/Electricity

|

80-140°C

|