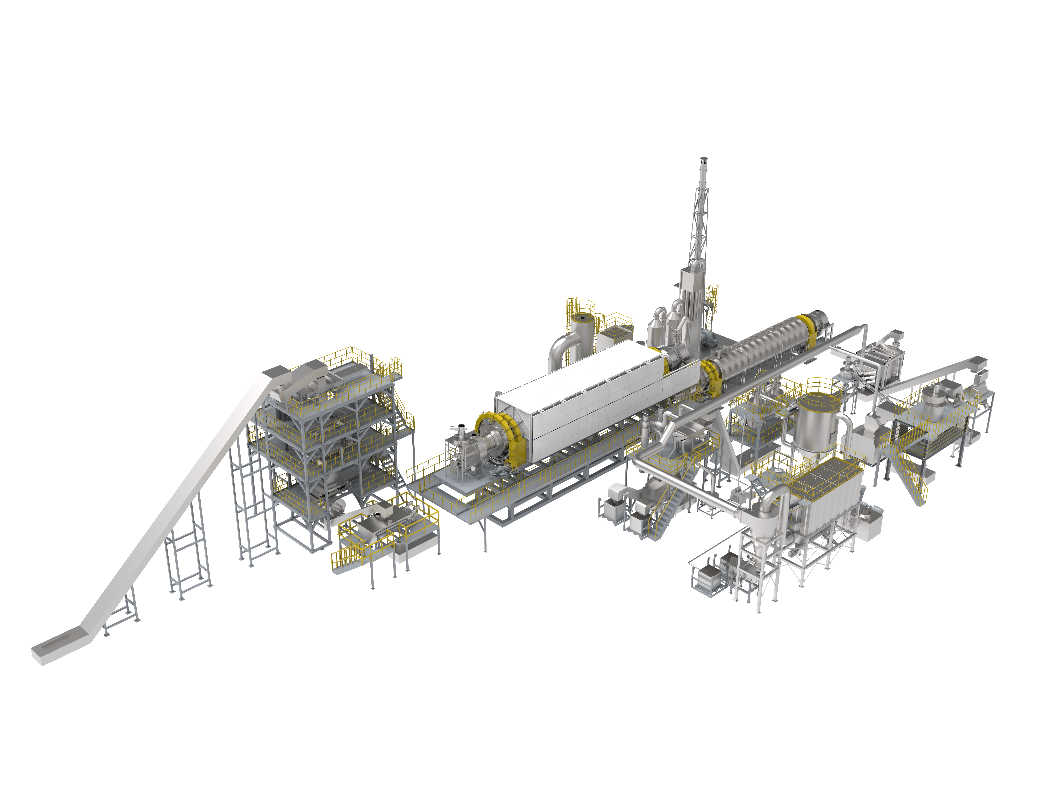

Waste NCM/LFP batteries undergo charged safe crushing under inert or special atmosphere, followed by drying to remove electrolyte, then high temperature pyrolysis to decompose separator, binder, and residual electrolyte in crushed materials. The process achieves dissociation of most electrode powders from current collectors, followed by multi-stage combined sorting to efficiently recover casings, copper, aluminum and electrode powders.

Exhaust gases generated during battery crushing and pyrolysis are treated via incineration pyrolysis and spray neutralization absorption to meet emission standards. Specifically, electrolyte is processed to eliminate it through combustion while minimizing natural gas consumption.

| Indicator | Black Powder Recovery | Copper & Aluminum Content | Copper & Aluminum Recovery Rate | Copper & Aluminum Recovery Purity | VOCs Emission | Fluoride Emission | PM Emission |

| Parameter | ≥98% | ≤1% | ≥98% | ≥95% | <40mg/m³ | <3mg/m³ | <20mg/m³ |