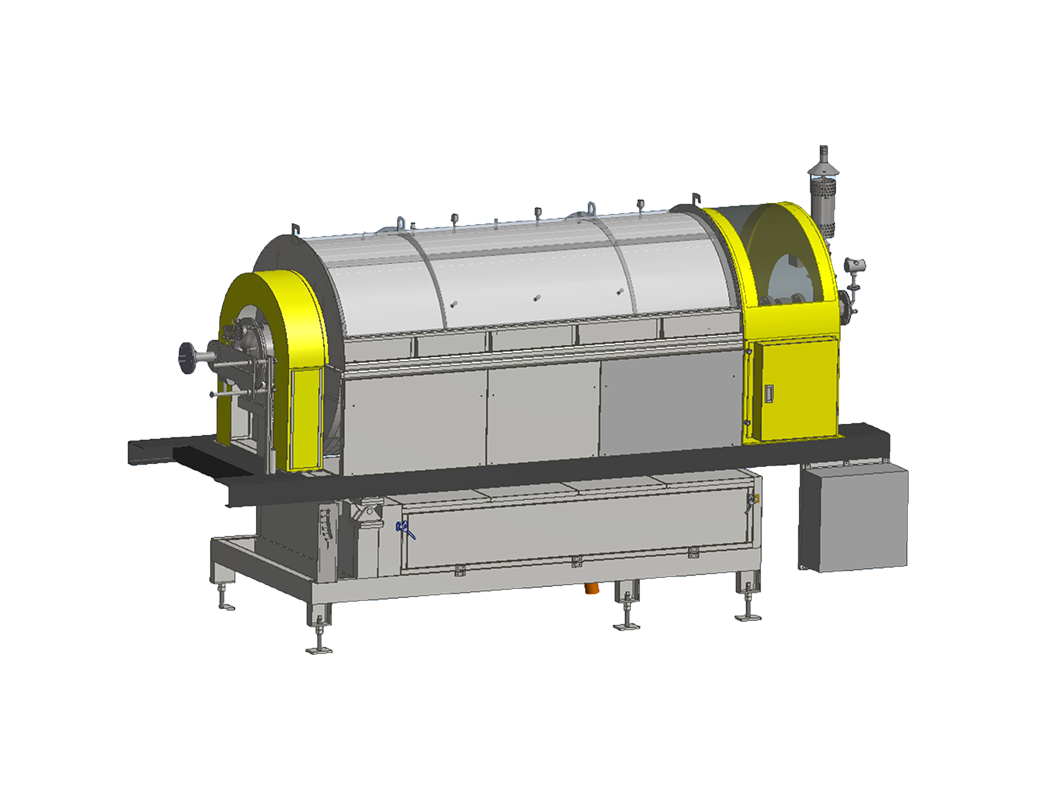

Silicon-Carbon CVD & Acetylene Coating Rotary Kiln

Specialized for CVD (Chemical Vapor Deposition) processes of silicon-carbon anode materials.

Options:

Product Feature

1. Short firing cycle: dynamic firing mode with rapid heat conduction speed, greatly shorten the firing cycle, relative energy consumption is better than other kilns;

Product Details

| Rated Temp | Control Accuracy | Atmosphere | Operation | Handling Capacity |

| 600℃ | ±1℃ | Nitrogen, silane, acetylene | Batch/Continous | 5-200kg/batch |

Do you want to learn more/collaborate with me?

It is the long-term support, understanding, and trust of our customers and friends towards Hengli that has enabled us to move forward with unparalleled passion and persistence on the path of intelligent manufacturing and green development. If you want to learn more about Hengli, please feel free to contact us.

0551-65846903