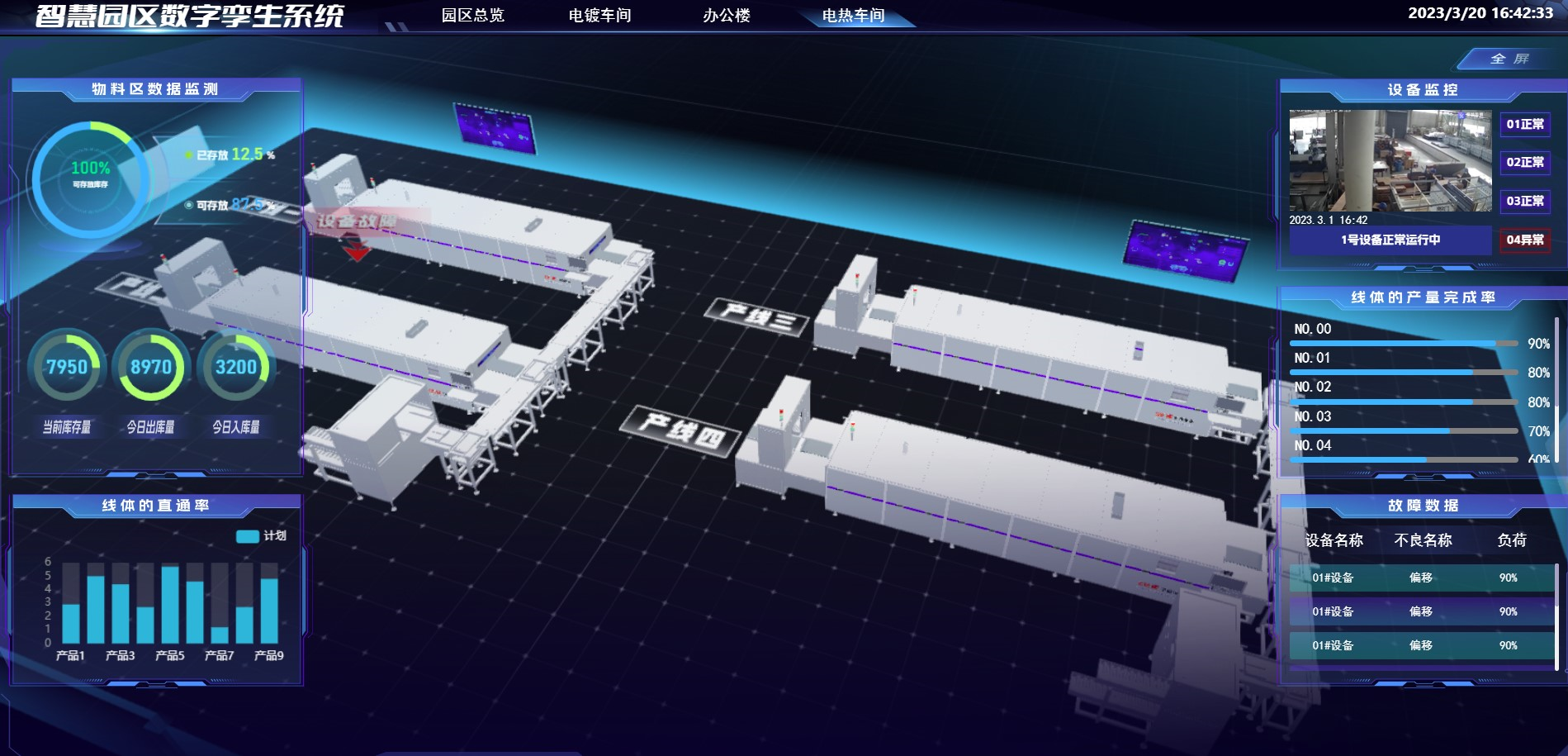

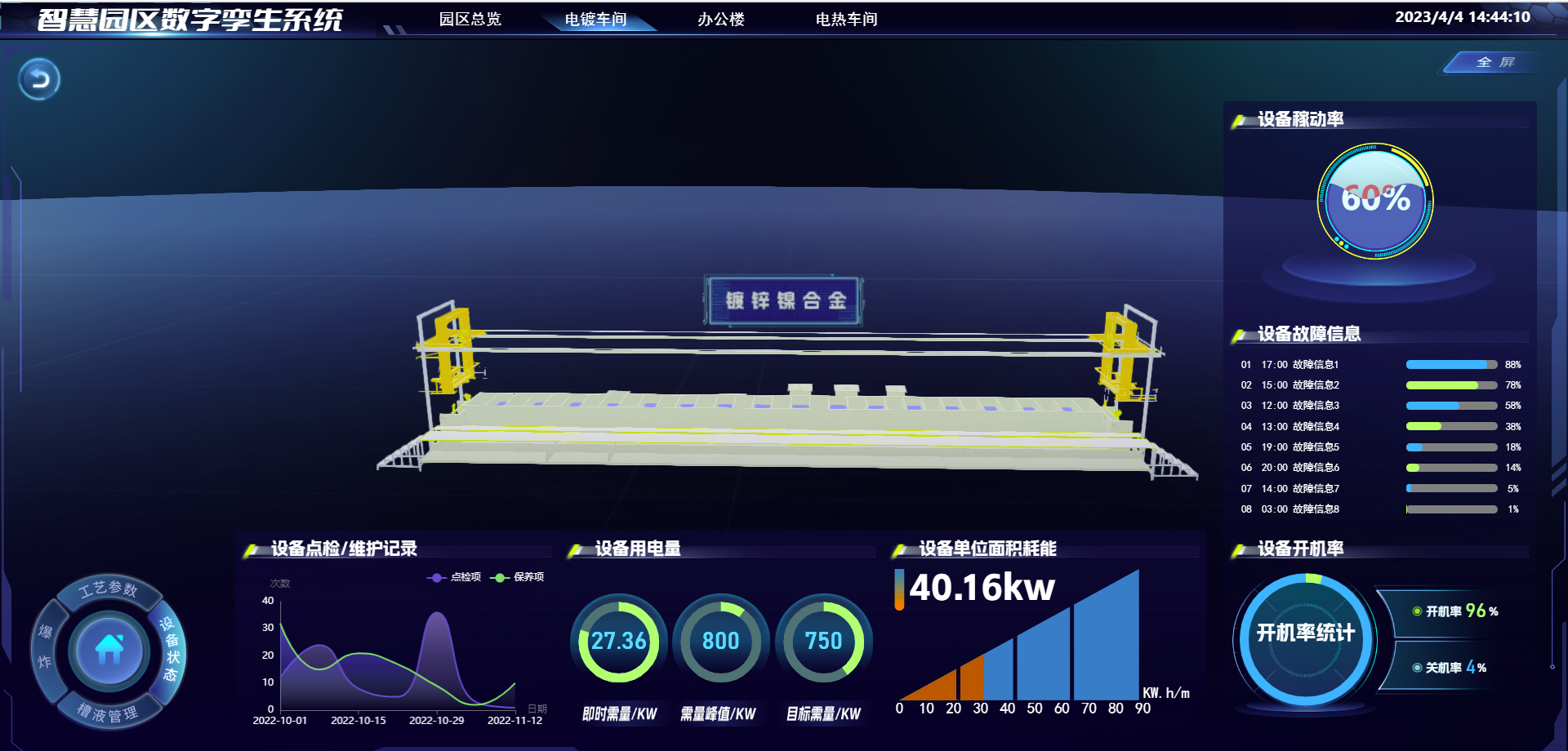

Digital virtual simulation center for production lines and equipment

It constructs high-precision equipment and line models, drives physical equipment through virtual models, realizes real-time state mapping and intelligent control, and efficiently supports production decision-making and operation maintenance.

It relies on 3D modeling technology and rendering engines. It models according to the layout of production line in the park, performs scenario-based rendering through simulation of real scenes, and connects with data from data acquisition and MES and other business systems to realize real-time status monitoring, energy consumption measurement management, and equipment abnormality alarms, and enables layered and penetrating display from the park, workshop, production line to equipment, achieving factory transparency and digitalization.